Bottle-top dispensers can provide precision, safety and convenience when dispensing liquids directly from reagent bottles. However, selecting the right bottle-top dispenser is crucial to ensure chemical compatibility, accuracy, and operational safety. In this article, we focus on the topic of how to choosing the right bottle-top dispenser for different chemical applications, exploring key factors and considerations for choosing the ideal dispenser.

What are the Functions of Bottle-top Dispensers

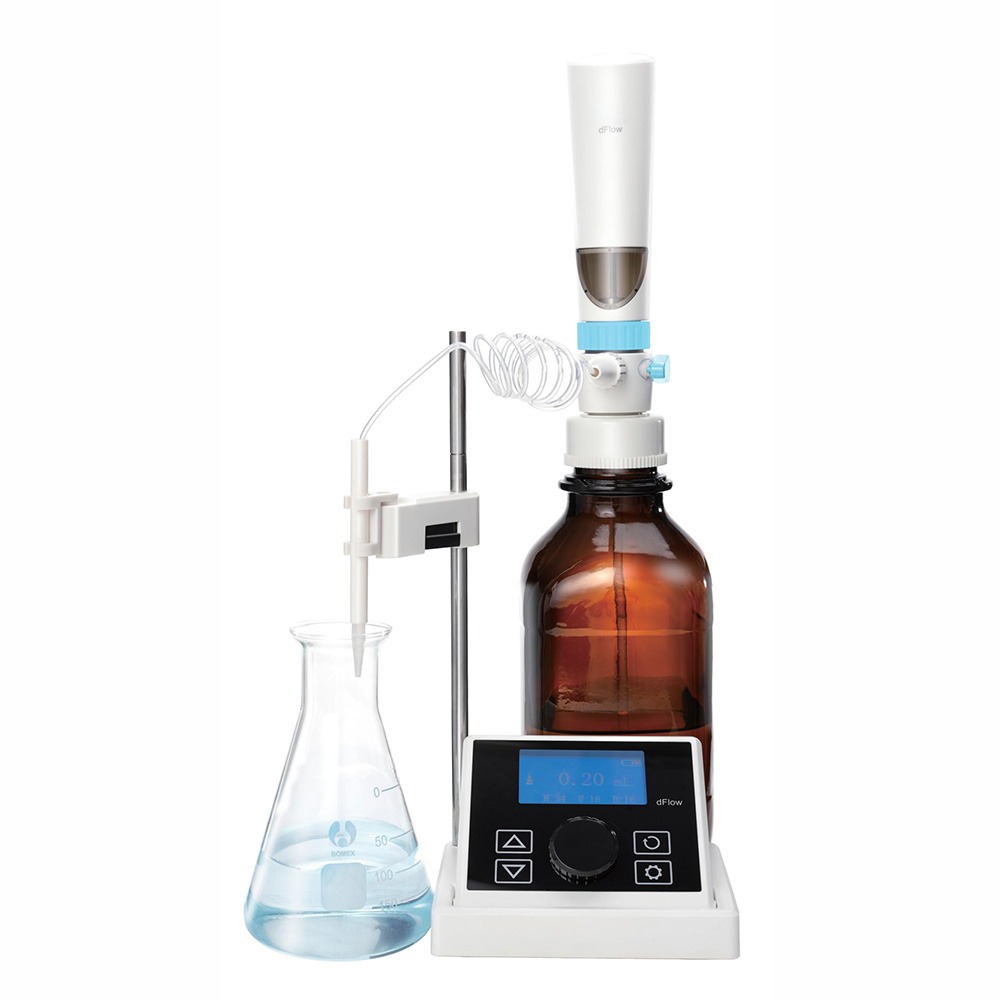

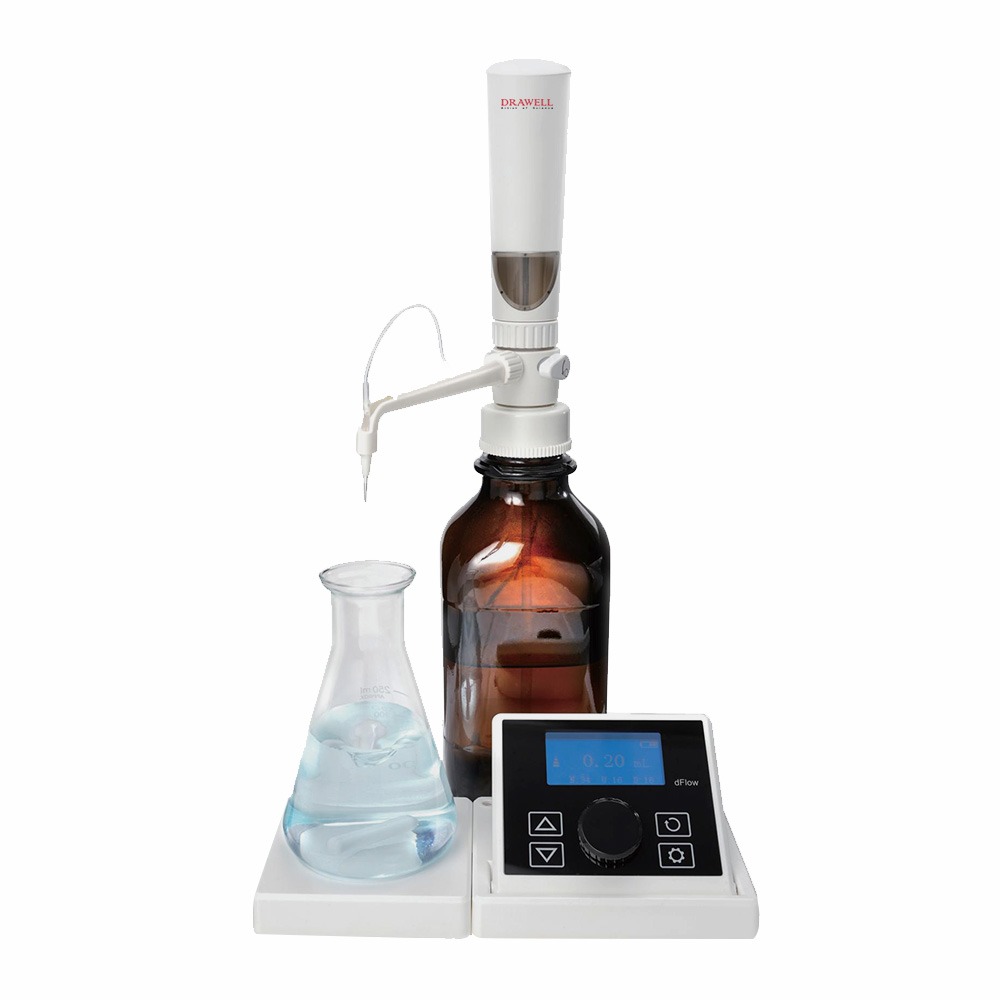

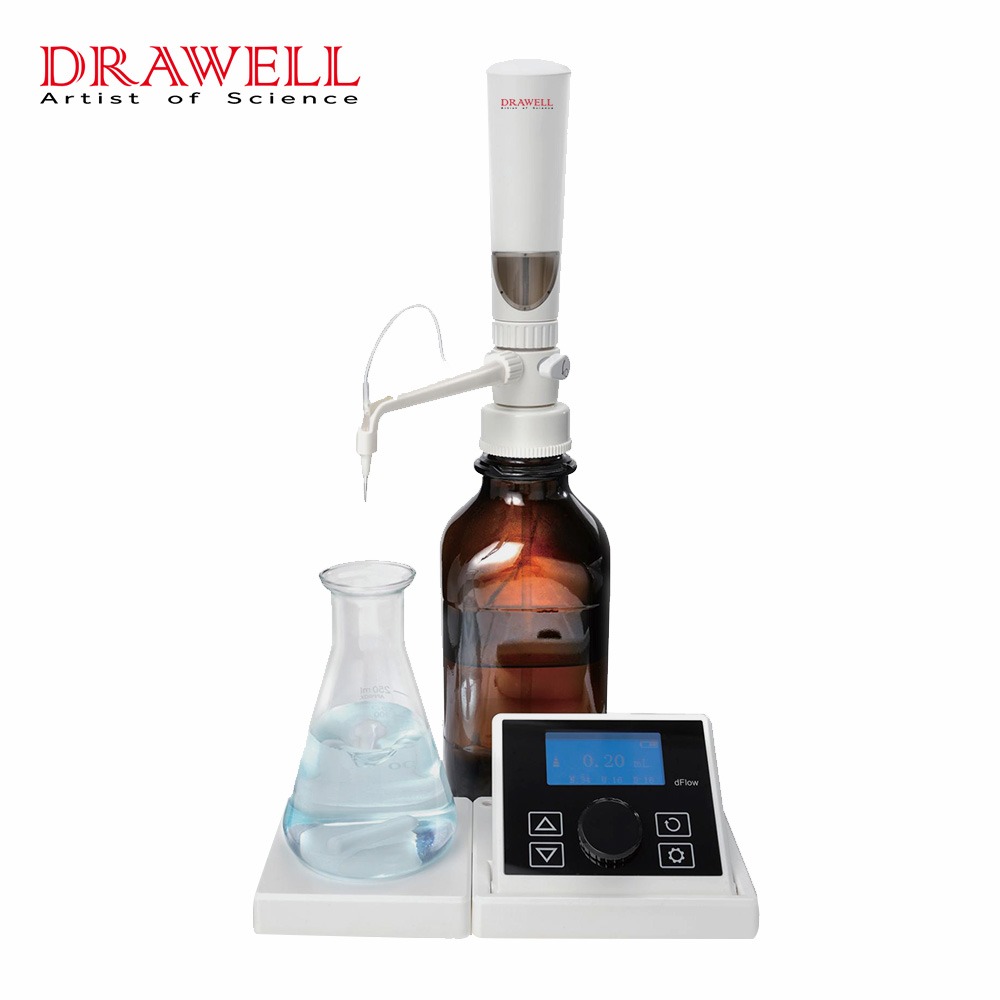

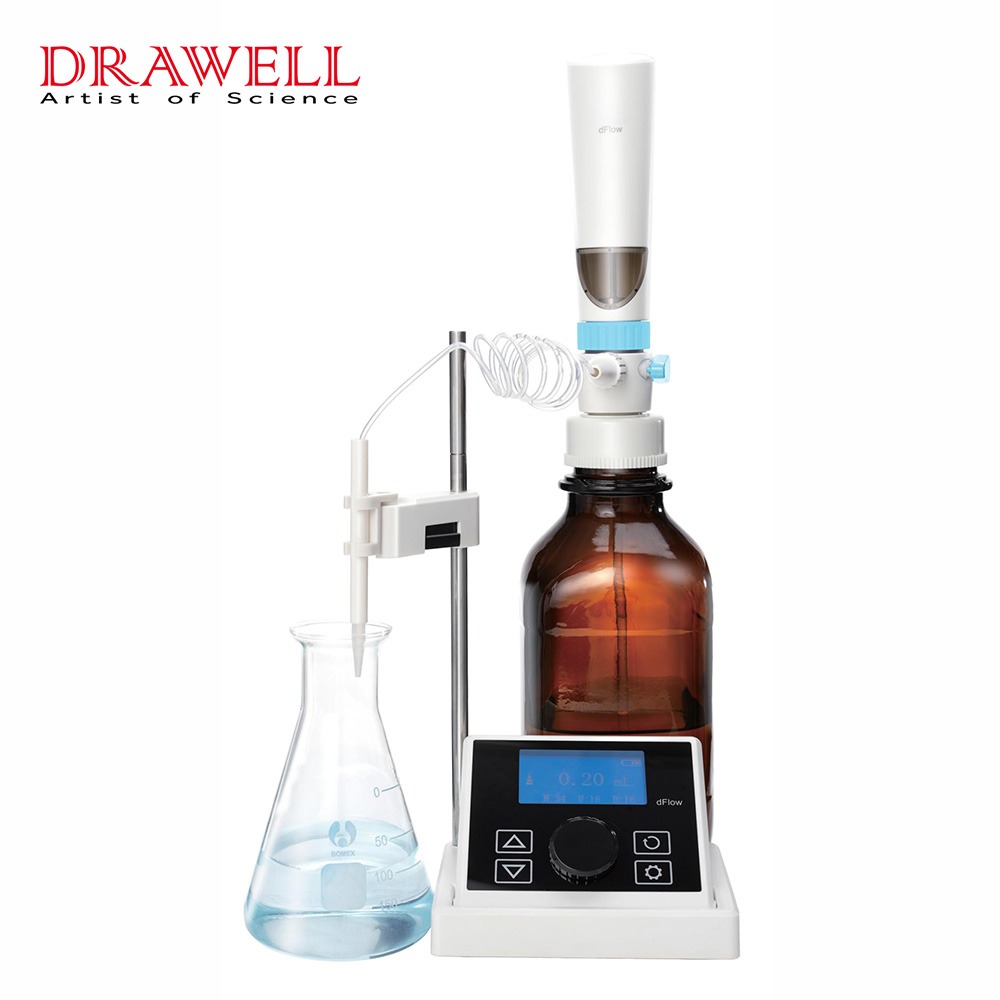

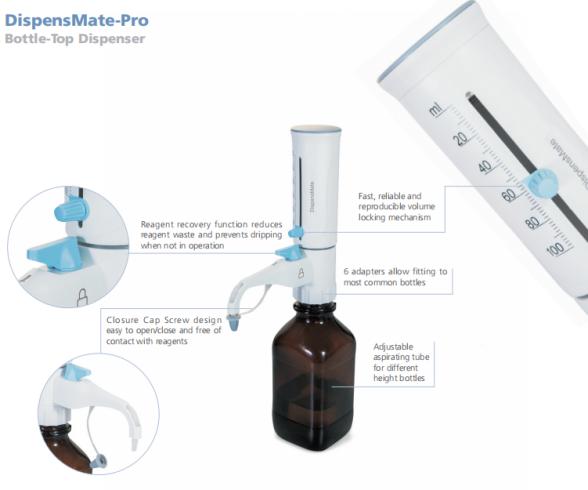

Bottle-top dispensers are precision laboratory instruments designed to safely and accurately dispense specific volumes of liquids directly from reagent bottles. They are commonly used in chemical, biological, and pharmaceutical labs to minimize spillage, contamination, and exposure to hazardous substances. Featuring components like pistons, valves, and discharge tubes, bottle-top dispensers offer controlled liquid handling, often with adjustable or fixed volume settings. Their design ensures consistent, repeatable results while enhancing lab safety and efficiency.

Types of Bottle-top Dispensers

| Type of Dispenser | Key Features | Suitable Applications |

| Fixed-Volume Dispenser | Delivers a pre-set, consistent volume; simple design | Routine dispensing where exact same volume is repeatedly needed |

| Adjustable-Volume Dispenser | Allows manual volume setting within a range | Versatile lab tasks, research, general use |

| Electronic Dispenser | Digital volume setting, high accuracy and repeatability | Analytical labs, pharmaceutical applications |

| Motorized Dispenser | Powered dispensing for minimal user strain; programmable | High-throughput labs, repetitive dispensing |

| Recirculating Dispenser | Built-in recirculation valve to reduce waste and priming | Handling hazardous or expensive chemicals |

| Organic Solvent Dispenser | Special seals and materials resistant to solvents | Organic chemistry labs, solvent handling |

| Autoclavable Dispenser | Fully autoclavable components for sterilization | Microbiology, biotech, sterile environments |

Key Factors for Choosing the Right Bottle-top Dispenser for Different Chemical Applications

1. Understand Your Chemical Compatibility

The first and most critical step is to match the dispenser’s materials with the chemical properties of the liquid being dispensed. Using incompatible materials can lead to degradation, leaks, or contamination. Here’s how to assess compatibility:

- Acids & Bases: Use dispensers made of PTFE, FEP, or borosilicate glass components, which resist corrosion.

- Organic Solvents: Choose models with glass pistons and FEP seals to prevent swelling or cracking.

- Saline or Aqueous Solutions: PP (polypropylene) based dispensers are generally sufficient.

- Highly Viscous or Volatile Liquids: Look for dispensers with specialized valves or safety features like vapor barriers.

Always consult the chemical compatibility chart provided by the manufacturer.

2. Determine the Required Volume Range and Accuracy

Bottle-top dispensers come in fixed or adjustable volume types. Choose based on your volume dispensing needs:

- Adjustable Volume Dispensers: Ideal for applications requiring flexibility across a range of volumes (e.g., 0.5 mL to 50 mL).

- Fixed Volume Dispensers: Provide higher accuracy for repetitive dispensing of a single volume.

- High-precision Dispensers: Opt for digital or stepper-motor-based models when dealing with small volumes or analytical applications.

3. Safety Features

Safety cannot be compromised, especially when dealing with hazardous, toxic, or volatile chemicals. A good bottle-top dispenser should include safety features like anti-drip systems, recirculation valves to minimize wastage and exposure during priming, and a closed design that prevents vapor release. Dispensers with integrated filters or splash protection further enhance safety during operation.

4. Ease of Use and Maintenance

Frequent use of dispensers can lead to operator fatigue if the device is not ergonomically designed. A smooth-action piston and a comfortable grip are essential for reducing strain. Additionally, dispensers that are easy to dismantle, clean, and sterilize—especially those with autoclavable parts—are particularly useful in labs with high sterility requirements. Simple maintenance extends the lifespan of the dispenser and ensures consistent performance over time.

5. Compatibility with Bottle Sizes and Lab Setup

Not all dispensers are universally compatible with every reagent bottle. Look for models that come with a variety of thread adapters, making it easier to use the same dispenser on bottles of different brands or neck sizes. Adjustable or angled discharge tubes are practical for labs with limited bench space or for use under fume hoods and biosafety cabinets, where space and access may be restricted.

6. Durability and Long-Term Value

Investing in a high-quality dispenser may come with a higher initial cost, but it often pays off through improved reliability, fewer repairs, and lower overall cost of ownership. A durable dispenser built from robust materials ensures performance consistency even after prolonged use, which is crucial in demanding lab environments.

7. Cost-Effectiveness

While high-quality dispensers may come with a higher initial price tag, they often offer better performance, fewer maintenance issues, and greater durability, making them more cost-effective in the long run. When evaluating dispensers, weigh the upfront costs against the potential benefits of reliability, safety, and ease of use.

Popular Chemical Applications and Matching Bottle-top Dispenser Types

Here’s a chart providing common chemical use cases with the most suitable Bottle-top dispenser types

| Chemical Application | Typical Chemicals | Recommended Dispenser Type | Key Considerations |

| Strong Acids and Bases | Hydrochloric acid, Sulfuric acid, Sodium hydroxide | Recirculating Dispenser with PTFE parts | High chemical resistance; anti-drip and closed system recommended |

| Organic Solvents | Acetone, Methanol, Ethanol, Hexane | Organic Solvent Dispenser | Solvent-resistant seals (FEP, ETFE); glass piston preferred |

| Sterile and Aqueous Media | Buffers, Water, Nutrient media | Autoclavable Dispenser | Must withstand sterilization; compatible with aqueous solutions |

| Viscous or Foaming Liquids | Detergents, Glycerol, Surfactants | Adjustable-Volume or Motorized Dispenser | Smooth piston action; wide bore design helps with viscous handling |

| Precise Analytical Dispensing | Reagents for titration, indicators, standards | Digital Dispenser | High precision and repeatability; often used in pharmaceutical labs |

| Routine Lab Work | Diluted acids, buffers, saline | Fixed- or Adjustable-Volume Dispenser | Cost-effective, durable for daily general-purpose tasks |

| Volatile or Toxic Chemicals | Toluene, Formaldehyde, Ammonia | Recirculating or Sealed-System Dispenser | Vapor control essential; closed system to prevent exposure |

| Biotechnology Applications | Cell culture media, Enzyme solutions | Autoclavable or Digital Dispenser | Sterility and precision are critical |

Final Thoughts

Selecting the right bottle-top dispenser isn’t just about fit or for and it’s about functionality, safety, and chemical compatibility. Through evaluating your specific application needs, chemical types, required safety features, durability, etc, you can ensure optimal performance, longevity and the safety of bottle-top dispensers for your lab personnel.

Drawell provides high-quality bottle-top dispensers designed to meet the diverse needs of various chemical applications. Whether you are working with strong acids, organic solvents, or sterile solutions, our dispensers are built with chemical-resistant materials like PTFE and FEP, ensuring durability and safety. With features like adjustable volume settings, precision dispensing, and easy maintenance, Drawell bottle-top dispensers offer a safe, efficient, and cost-effective solution to your liquid dispensing needs.

Related Products Recommendation

What Next?

For more information, or to arrange an equipment demonstration, please visit our dedicated Product Homepage or contact one of our Product Managers.