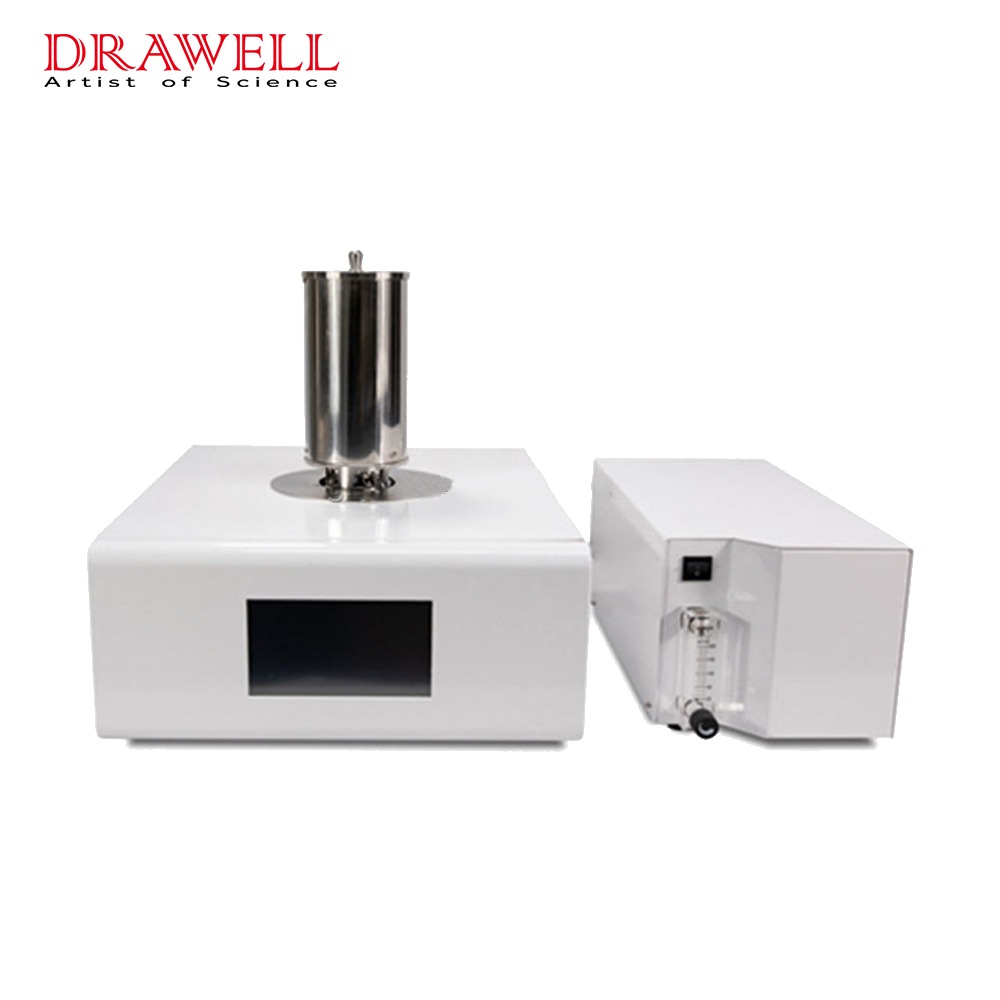

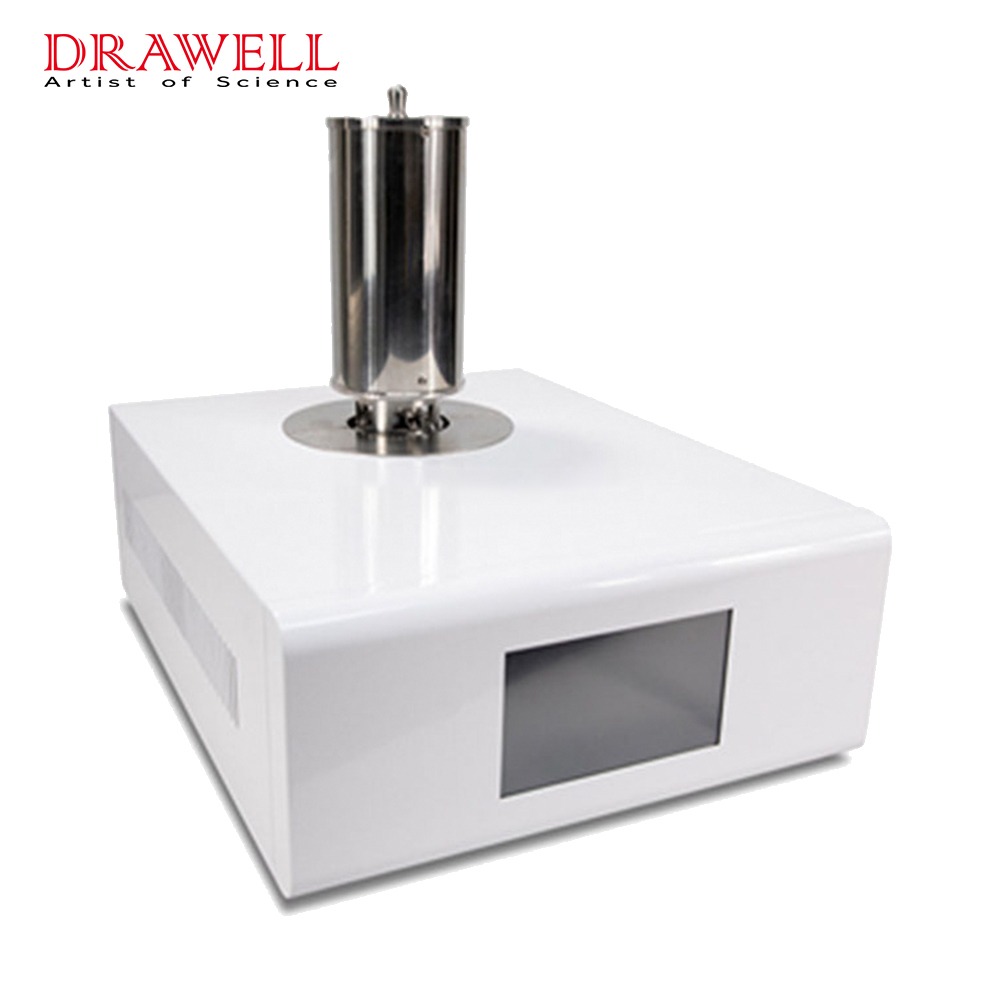

Synchronous Thermal Analyzer BXT-STA-200

Synchronous thermal analyzer combines thermogravi metric analyzer TGA with differential thermal analyzer DTA or differential scanning calorimeter DSC. The same sample can be used to obtain the information of TGA and DTA or DSC in the same measurement.

DSC: melting, crystallization, phase change, reaction temperature and reaction heat, combustion heat, specific heat…

TGA: thermal stability, decomposition, redox, adsorption and desorption, free water and crystal water content, calculation of component ratio, etc.

Main Features

- The furnace body is heated by double-row winding of precious metal nickel-cadmium alloy wire, which reduces interference and is more resistant to high temperatures. Advanced control system. The temperature can be controlled quickly and stably.

- The tray sensor is made of precious metal nickel-cadmium alloy, which has the advantages of high temperature resistance, oxidation resistance, and corrosion resistance.

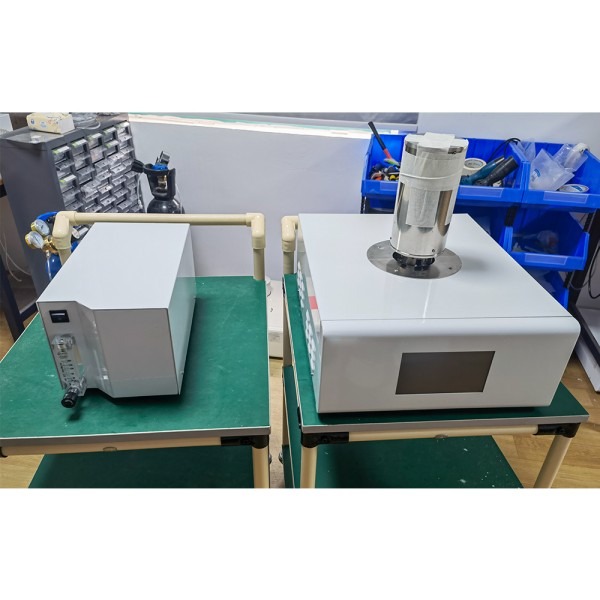

- The power supply and circulating heat dissipation part are separated from the main machine to reduce the influence of heat and vibration on the micro-thermal balance.

- Adopt top-opening structure, easy to operate. It is difficult to move the furnace body up to place the sample, and it is easy to damage the sample rod.

- The host adopts a water area constant temperature device to isolate the thermal influence of the heating furnace body on the chassis and the micro-thermal balance.

- Automatically generate and print test reports. The software has built-in test records, data processing and report formats, and automatically issues test reports.

- The furnace body can be replaced according to customer requirements

Controller software advantages

- Using imported 32bit ARM processor Cortex-M3 core, sampling speed and processing speed are faster.

- 24bit four-channel sampling AD collects DSC signal, TG signal and temperature T signal.

- The power supply and water circulation part are individually controlled by 8bit single-chip microcomputer to separate the host and the cooling part without interfering with each other, but the two are closely connected, and the cooling part is controlled by the host.

- The USB two-way communication is adopted between the software and the instrument, which fully realizes remote operation. The parameter setting of the instrument and the operation stop of the instrument can be carried out through the computer software.

- 7 inch full color 24bit touch screen, better man-machine interface. TG calibration can be achieved on the touch screen.

Technical Parameters

| Temperature range | Room temperature~1600℃ |

| Temperature resolution | 0.01℃ |

| Temperature fluctuation | ±0.1℃ |

| Heating rate | 0.1~100℃/min |

| Cooling rate | 1~20℃/min |

| Temperature control method | heating, constant temperature, cooling |

| Cooling time | 15min (1000℃ …100℃) |

| Measuring range of balance | 1mg~2g |

| Resolution | 0.01μg |

| DSC range | 0 ~ ±500mW |

| DSC resolution | 0.01mW |

| Constant temperature time | 0~300min arbitrarily set |

| Display mod | Chinese character large-screen LCD display |

| Atmosphere | inert, oxidizing, reducing, static, dynamic |

| Atmosphere device | Built-in gas flow meter, including two-way ga switching and flow rate control |

| Software | Intelligent software can automatically record th TG curve for data processing and pri experimental reports |

| Data interface | Standard USB interface, special software, (free software upgrades from time to time) |

| Power supply | AC220V 50Hz |

Standard

- ISO 11358 Plastics – Thermogravimetry (TG) of Polymers

- ASTM E793 Standard Test Method for Enthalpies of Fusion and Crystallization by Differential Scanning Calorimetry

- D IN 51004 Thermal Analysis; Determination of Melting Temperatures of Crystalline Materials by Differential Thermal Analysis

- D IN 51006 Thermal analysis (TA); Thermogravimetry (TG); Principles

- D IN 51007 Thermal Analysis; Differential Thermal Analysis; Principles

- GB/T 19466.2-2004 / ISO 11357-2: 1999 Part 2: Determination of glass transition temperature; GB/T 19466.3-2004 / ISO 11357-3: 1999 Part 3: Determination of melting and crystallization temperature and enthalpy;

- GB/T 19466.4–2016/ISO 11357-4:1999 Part 4: Determination of specific heat capacity;

- GB/T 19466.6-2009/ISO 11357-3:1999 Part 6 Oxidation induction period: Determination of oxidation induction time (isothermal OIT) and oxidation induction temperature (dynamic OIT)