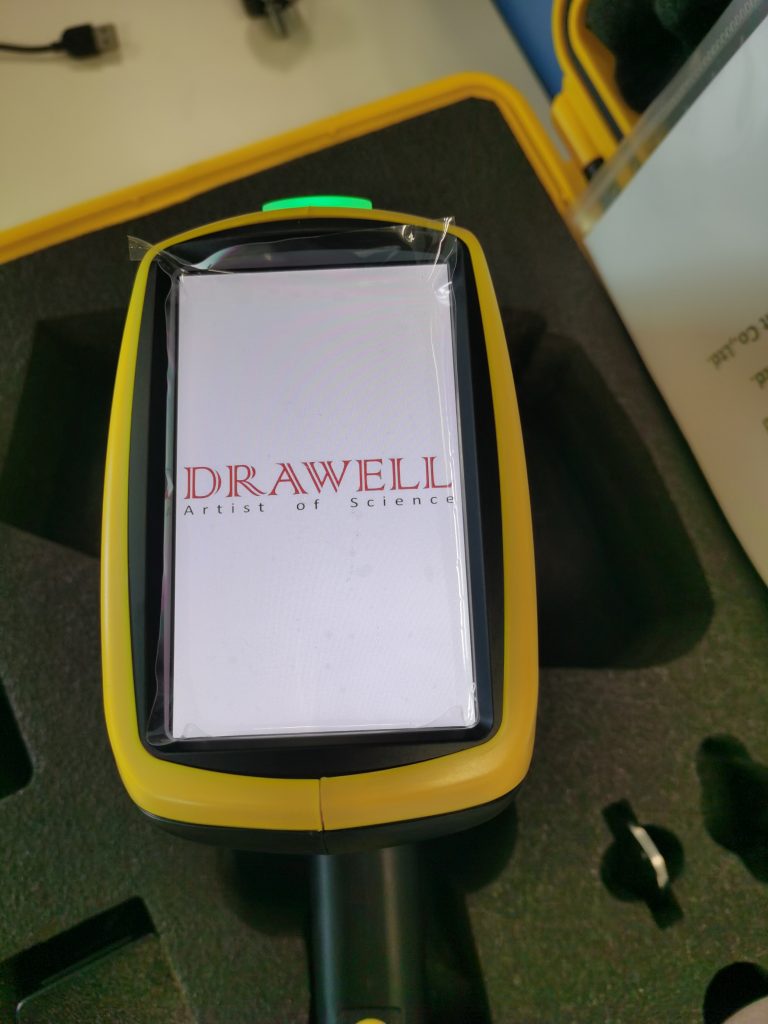

TrueX 800 Alloy Analyzer

TrueX hand held alloy analyzer (XRF) is a powerful weapon in material identification (PMI) in the production of high temperature and high-pressure boilers, containers, pipes, etc; metal identification in iron and steel metallurgy, nonferrous metals, aerospace, weapons, submarine vessels, etc; metal material identification in engineering installation and construction projects in areas of the petrochemical refining, fine chemical, pharmaceutical, power plant, aerospace, etc to ensure equipment and material acceptance meet the project specified requirements; scrap metal recycling industry.

Performance Features of TrueX 800 Alloy Analyzer

- Small, light, and easy to carry.

- High-speed processing chip, advanced algorithm, and high-responsive software, resulting in even faster analysis.

- High-performance X-ray Tube, Ultra-high Resolution Detector combined with Digital Multi-channel Processing Technology, yielding super-high detection resolution.

- Indicator lights flash on both sides for safety purposes during measurement, i.e., the built-in double beam technology will automatically sense whether there is a sample at the measurement window.

- Industrial resistive touch screen, superior to capacitor screen in back-light and clearer against sunlight in the field. At the same time, people don’t need to take off gloves when they are operating machines in some particular environment.

- TrueX utilizes anti-slip, abrasion resistance, and streamlined design, which is light and easy to carry. It also integrates the new high-speed digital multi-channel technology, the new library grade base identification system, and the super-FP algorithm. These features allow it to measure elements faster, with higher accuracy and greater repeatability.

- Intelligent battery management exerts real-time monitoring of the residual capacity of the battery and backup battery through the MSBUS bus.

- Automatic switch to standby mode when not used and recovery after the machine is picked up, which saves power and extends working time; moreover, TrueX has a gravity sensing system which shuts down instrument automatically when it accidentally falls down, another safety consideration; TrueX will also give out an alarm when ambient temperature or humidity exceeds the scope of application.

- TrueX adjusts the air pressure factor automatically based on the altitude it has detected. This function increases the excitation effect of light elements by 40% and that of rare earth elements by 30%.

- TrueX is supportive of battery hot plug, hence battery can be replaced without powering off the machine.

- On TrueX, users can customize the reports by adding their company logos, addresses, test results, spectrum, and others (such as product description, the origin of products, and batch number).

- TrueX is built with double beam technology which can automatically sense whether there is a sample at the measurement window. This is also a safety and protection feature. The brightness of the display of TrueX is automatically regulated according to environment brightness.

- TrueX can be configured and maintained in a remote way via the Internet.

- TrueX can build a three-dimensional element content distribution graph allowing for a fast estimate of mineral reserves or the extent of geological disaster with the built-in GPS for latitude and longitude reading combined with a 3rd party GIS analysis software.

- Truex’s new algorithm optimizes the spectral resolution, so lower detection limits can be achieved, which are comparable with even large-scale lab instruments.

- TrueX Ultra-short optical™ path design can significantly improve light element excitation effects, without the fall/fill condition.

- TrueX has a built-in environmental sensing system covering conditions such as temperature, dust humidity, and others.

Application Features of TrueX 800 Alloy Analyzer

1. Excellent Performance

TrueX shows element symbols in both English and Chinese. With high precision, high testing speed and comparable results to even that of laboratory equipment, TrueX displays alloy grade and elements percentage content (up to three decimals) and ppm content in an apparent way.

2. One-touch operation

TrueX test lasts only a few seconds and identification of alloy grades takes only 1 or 2 seconds. This facilitates operation by non-technical users.

3. Nondestructive testing (NDT)

TrueX test does not damage or have any adverse effect on the use of samples. No damage is foreseen in the entire test process.

4. Drawell analysis software

Drawell analysis software is a professional analysis software that enables the users to easily configure passwords, customize analysis reports attached with company LOGO and implement remote control of the machine; users can edit alloy grade library, add their own grade number or define their own company’s alloy brands; the software also allows automatic calibration of instrument and diagnosis of problems in a remote way; the software can be updated via the Internet.

5. Scrap metal recycling and sorting

Scrap metal recycling, reuse, and on-site analysis and sorting. TrueX offers a rapid and reliable identification of the scrap metals when scrap metals are transacted between buyers and sellers. TrueX delivers quantitative element analysis of iron alloy, copper alloy, aluminum alloy, copper-iron alloy,lead-tin alloy, mixed alloys, etc, and rapid identification and sorting of these alloys on the site.

6. Application fields, safety, and standards

TrueX is suitable for alloy material identification (PMI) for incoming inspection; material inventory management;re-inspection of construction materials in petrochemical construction, metal smelting, pressure vessel, power plant, petrochemical industry, fine chemical, pharmaceutical, aerospace, and other industries to avoid serious safety accidents resulting from mixed or unqualified materials. TrueX is in compliance with ANTM standards, China National Standard (GB), UNS, electric industry standards (DL), API, JIS, GMP, TSG, Mechanical Industry standards (JB), etc.

7. Quality Control, Quality Assurance (QC/QA), and Error-proofing(PKKA – YOKE)

In the metal processing and manufacturing industry, quality control and quality assurance (QC/QA) and error proofing (PKKA – YOKE) of materials (raw materials), semi-finished products and finished products are indispensable. The use of mixed or unqualified materials will bring losses to the company. This is true for companies ranging from small metal processing plants to large aircraft manufacturers.

8. Data Processing and Enterprise Resource Planning (ERP)

Data can be transferred via USB, WIFI, and Bluetooth and stored in excel, pdf, or other formats. Users can customize the reports by adding their company logos, addresses, test results, spectrum, and others (such as product description, the origin of goods, and batch number); the i-cloud data storage service is optional. Data can transport to Enterprise Resource Planning (ERP) system.

Application Fields

- Nondestructive, rapid, and accurate analysis of alloy elements and alloy grade identification on the site

- Metal identification /scrap metal sorting

- QA/QC management in metal production, processing, casting, etc

- Medicine and biological medicine

- Identification of positive materials, oil refining, and petrochemical industry

- Thermal power plant, hydroelectric power station, nuclear power plant

- Accurate element analysis of raw material and PMI identification so as to meet production needs and ensure the security of equipment and materials used in the process.

Elements to be Analyzed and Test Modes

|

TrueX 800 elements analyzed |

|

|

|

Scope of elements in standard test mode can be extended if there is such a need. |

|

TrueX 800 |

can analyze Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, W, Zr, Nb, Mo, Ag, Cd, Sn, Sb, Pb, Bi, Au and LE ,total 21 elements. |

Instrument specification

The ARM architecture Cortex-A8 1 GHz

System Processor: The Android 4.2 operating system/80MHZ ADC digital pulse processor/4096 MCA channel, 32GB memory

Display: Industrial resistive touch screen with a screen size of 4.3″

Data storage: Built-in 32GB memory, 300,000 spectral data, and spectrum can be stored

Operating Temperature: -20℃~+50℃

Operating Humidity: ≤90%Limit of

Library of extensible and customizable alloys

Ability to make measurements on pipes, flat surfaces, surface integrals, and welds

Method of analysis: the x-ray energy dispersive method for analysis of fluorescence

Simultaneously detect elements: simultaneously detect dozens of elements

Processor and RAM: CPU: 1GB RAM: 1GB

The standard configuration: 32G

Range content: ppm ~ 99.99%

15 seconds reading time

GPS, WIFI: integrated into the system

Battery: lithium battery, which can be loaded with a maximum capacity of our 6800Ah can operate continuously for 8 hours; Equipped with a high voltage (110V-220V) adapter, can work under current alternative

Sensor resolution: solid, liquid, powder

Sensor resolution: low resolution can be 139eV

Excitation source: 40KV / 100mA-Ag window miniature tube anode X of light and high voltage source

Collimator and filter: sights of 4.0 or 2.0 of diameter, automatic switch of 8 filters. 12 kinds of groups, plus mode consisting of world, can satisfy different types of tests of samples

Display: touchscreen TFT – LCD, resolution of 640 * 480.

Protection against water, dust, and shock

Test window: 12mm.

Charging system gas: Helium charging system of ordinary pressure.

Security: standalone password manager mode.

data transmission: digital multi-channel technology, the transmission of data SPI, a quick scan, count rate, waterproof miniature USB, which can be connected to the desktop computer.

Alloy Family

- Iron-based alloy series (stainless steel, chromium/molybdenum alloy steel, low alloy steel, tool steel, seamless steel)

- Nickel-based alloy series (nickel alloy, nickel/cobalt alloy)

- Cobalt-based alloy series

- Titanium-based alloy series

- Copper-based alloy Series (bronze, brass, copper and nickel alloy, etc.)

- High-temperature alloys (molybdenum tungsten alloy)

- Aluminum-based alloy

The super-FP algorithm is capable of detecting accurate metal element content and identifying material without switching mode!

TrueX hand-held alloy analyzer (XRF) is a powerful weapon in material identification (PMI) in the production of high-temperature and high-pressure boilers, containers, pipes, etc; metal identification in iron and steel metallurgy, nonferrous metals, aerospace, weapons, submarine vessels, etc; metal material identification in engineering installation and construction projects in areas of the petrochemical refining, fine chemical, pharmaceutical, power plant, aerospace, etc to ensure equipment and material acceptance meet the project specified requirements; scrap metal recycling industry.

TrueX is applicable to quality control, material classification, alloy identification, accident investigation, etc, which tackles the fundamental difficult problem of raw material analysis. As an innovation of many modern technologies, it is a great helping hand in these applications. Users can personalize the analyzing system according to their own needs.

Truex’s built-in alloy library contains 380 kinds of alloys, as well as other special alloys for mold, electric power, petrochemical, and other industries, which simplifies the conversion of alloys from one country to another. Besides, it has two built-in libraries that the users can define by themselves to extend alloy brands. Therefore, it can extend to as many as 600 alloy brands and test more than 1,000 kinds of alloy materials.

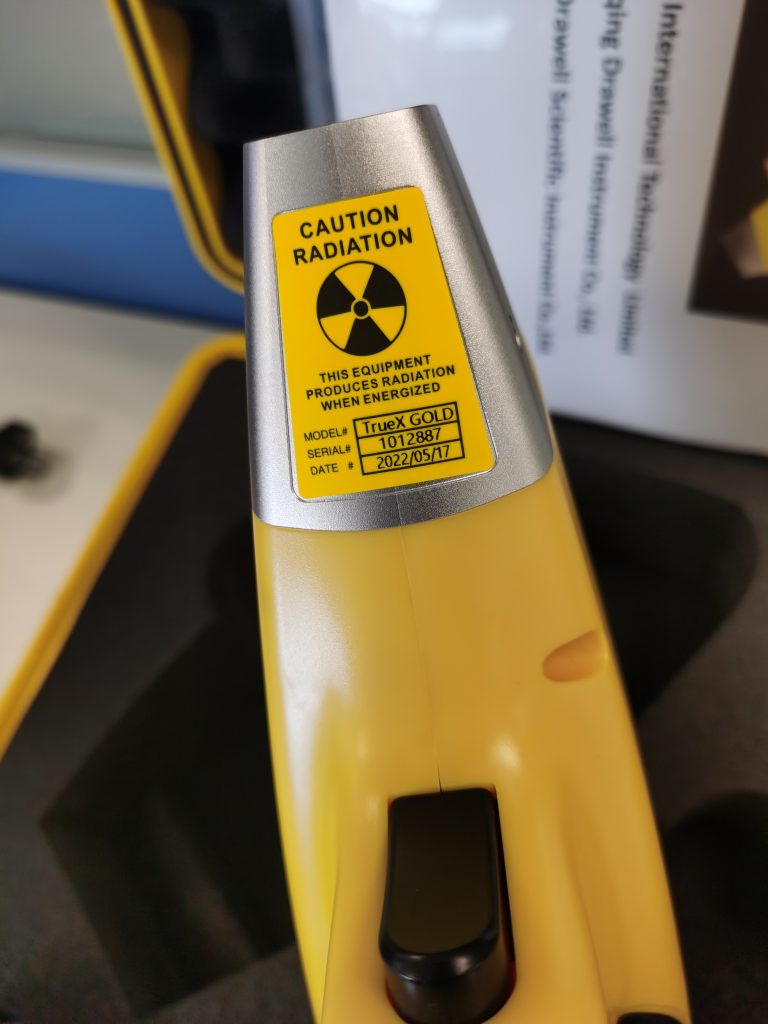

Technical parameters and specifications

|

Weight |

1.6Kg(with battery). |

|

Dimensions |

254x 79×280 mm(LxWxH). |

|

Excitation source |

50KV/200μA maximum pipe pressure pipe flow can be adjusted freely,Agtarget (standard),Au,W,Rh target(optional). |

|

Detector |

BOOST Si-PIN detector |

|

Range of detection |

Elements between Mg and U. |

|

Display system |

Industrial resistive touch screen with screen size of 4.3″. Proprietary operating system software and sound waves. Multiple languages including English and Chinese. And it automatically adjusts display brightness according to the environment brightness. |

|

Data processing |

32GB memory USB, bluetooth, WIFI, or liked to the Internet; instrument can be configured and repaired remotely. Data can be exported via EXCEL or PDF. Users can customize the reports by adding their company logos, addresses, test results, spectrum and others (such as product description, origin and batch number). |

|

Heat dissipation |

Equipped with a dedicated T-shaped radiator to dissipate the heat;no need to wait for cooling of detector time again. |

|

Safety |

Built-in double beam technology can automatically sense whether there is a sample at the measurement window. This is also a safety and protection feature. Waterproof, dust-proof and shockproof suitcase Drawell Safety Band; |

|

Power supply system |

Intelligent battery management through MSBUS bus, real-time monitoring of the residual capacity of battery and backup battery. The battery complies with air transport regulations of dangerous goods. A single battery can last 8 hours. |

Real-test Values of 316 samples

| Reading | Mode | Cr% | Mn% | Mo% | Ni% |

| No1 | ALLOYS | 16.56 | 1.22 | 2.03 | 10.18 |

| No2 | ALLOYS | 16.66 | 1.29 | 2.01 | 10.15 |

| No3 | ALLOYS | 16.61 | 1.20 | 2.05 | 10.05 |

| No4 | ALLOYS | 16.62 | 1.19 | 2.00 | 10.03 |

| No5 | ALLOYS | 16.68 | 1.18 | 2.05 | 10.15 |

| No6 | ALLOYS | 16.67 | 1.22 | 1.99 | 10.10 |

| No7 | ALLOYS | 16.62 | 1.25 | 2.04 | 10.16 |

| No8 | ALLOYS | 16.5 | 1.16 | 2.03 | 10.20 |

| No9 | ALLOYS | 16.7 | 1.19 | 2.01 | 10.17 |

| No1 | ALLOYS | 16.63 | 1.20 | 2.03 | 10.08 |

| Standard value | 16.68 | 1.22 | 2.03 | 10.11 |

Real-test Values of 316 Samples

1. Quality warranty

Drawell commits that the TrueX handheld spectrometer is fabricated with fine-grade materials and top-notch workmanship. It is brand new, never used, and in full compliance with the quality provision of this Contract. TrueX warranty is 12 months starting from the date of final acceptance of the goods/commissioning of the machine.

2. Technical training

Operating Manual of TrueX Handheld Spectrometers

Maintenance Manual of TrueX Handheld Spectrometers

3. After-sale service

Over the years, Drawell has sold XRF instruments to many global users. In order to provide better technical support and service, it shall be committed.

1. services including

a)Drawell shall provide after-sales service to all products it has sold worldwide.

b)Drawell shall provide a one-year warranty for the spectrometer it has sold worldwide.

c)Drawell shall provide a one-year warranty for X-ray Tube (X-ray tube)and Detector (Detector).

d)Drawell shall provide a one-year renewal warranty for the replaced components in case there is any replacement of them during the repair of the machine.

2. The following physical damage is not covered by warranty.

a)instrument is impacted by great force that the internal impact sensor changes from white to red;

b)Detector is broken

c)PDA is broken;

d)Instrument body is broken;

e)Loss of accessories

f)Loss of components

g)Water coming into the instrument

3. In case the instrument is not able to operate, the customer can call after-sales service for help; we offer 3 types of repairs:

a)Internet repair: if the customers are in foreign countries or remote areas, we can offer them first the INTERNET repair service.

b)Phone repair: customers called over the phone to explain explicitly the problem and our technical staff will instruct them to solve the problem.

c)On-site repair: in case the phone repair fails, our technical personnel will go to the site to repair the instrument within 72 hours after the problem is reported;

4. Out-of-warranty service: upon expiry of the warranty period, all customers are still entitled to out-of-warranty service during the working life of the instrument.

5. Privilege in out-of-warranty service: customers shall have the privilege to get preferential prices on the components when they maintain their instrument during the out-of-warranty period as long as they maintained it beforehand.

Product Display

Customer Feedback of TrueX 800 Alloy Analyzer