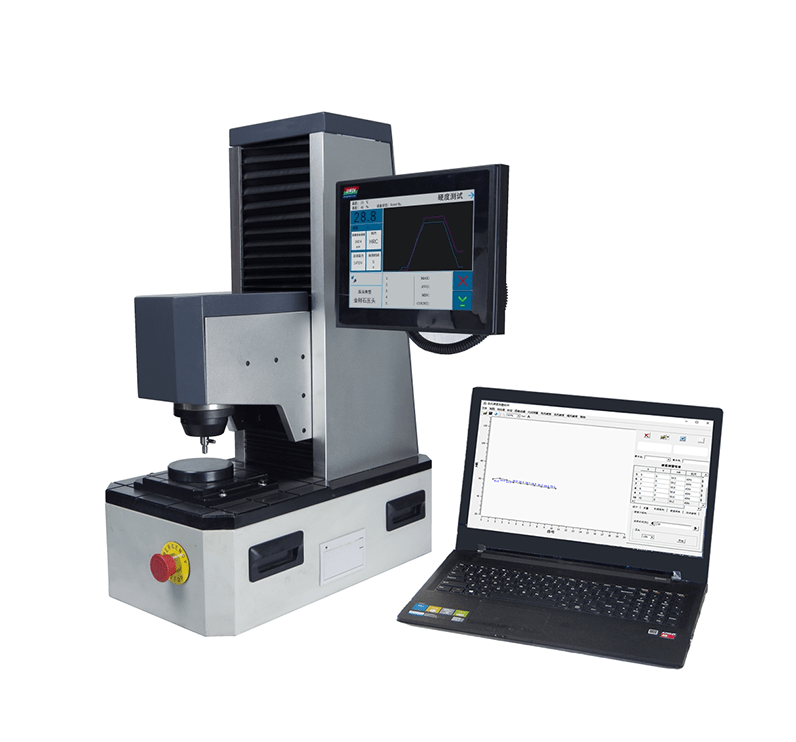

Full Automatic Precision Rockwell Hardness Tester JMHRS-150-XYZ

The system adopts high-speed precision step control technology to realize the whole process of continuous tracking and control of the afterburning process. High precision displacement sensor is used in Bathymetric system, and the resolution of minimum hardness is 0.1HR. The loading table is fixed and the hardness is tested by moving the indenter up and down. Fixed test-bed can eliminate the coaxiality error caused by the up-down rotation of traditional screw, greatly improve the accuracy and repeatability of testing, and also increase the stability and efficiency of machine work. Novel appearance, complete functions, easy operation, clear and intuitive display, stable performance, is a set of mechanical and electrical integration of high-tech products.

Introduction of JMHRS-150-XYZ Rockwell Hardness Tester

The instrument eliminates the weight and adopts the electric loading and unloading test force to test the hardness of all Rockwell scale and surface Rockwell scale. The machine has full automatic and manual operation function, XYZ automatic control, suitable for end quenching test; external PC computer has data statistics function, can calculate extreme value, average value, standard deviation, etc., and can also establish corresponding statistical database. Moreover, in the whole test process, PC real-time collects pressure and depth data and derives them for elastic modulus research. Statistical databases allow input of test data for other devices and can be used for statistical analysis. According to the user’s requirements, the test report can be customized, and the test parameters, test results and chart curves can be selected in the report. The test results and test reports can be transmitted through the network, and other computers can be allowed to call these data in order to realize network management.

End quenching test is a standard method to determine the hardenability of a metal and alloy material. At present, the commonly implemented standards at home and abroad are: GB/T 225, ISO 642, JIS G0561, SAE J406 and ASTM-A-255.

The principle of end quenching test is: according to HRC hardness scale, the hardness values of multi-points are measured at certain intervals along the axis direction from the quenching end of the end quenched sample. In the coordinate system where the longitudinal coordinate is the hardness value and the abscissa is the distance, the position of each measurement result is marked, the points are connected, and a continuous curve is drawn. The testing process of the end quenching test system is: putting the end quenching sample into the rectangular groove on the upper part of the worktable, manually rotating the drum wheel to move the test platform, with a digital scale, synchronously indicating the moving displacement; making the sample start from the quenching end, along the axis direction, at a certain interval, according to HRC hardness scale, testing the hardness of multiple points. Hardness value is automatically output to computer through USB interface, processed by “end quenching test analysis software”. End quenching curve and various parameters, hardenability and hardening layer analysis are displayed on computer.

Functional Characteristics of JMHRS-150-XYZ Rockwell Hardness Tester

- High-precision step-control loading system, test-bed fixed, high-precision and fast testing can achieve remote control.

- Testing 15 Rockwell hardness scales and 15 surficial Rockwell hardness scales

- Resolution of displacement sensor is 0.1 M

- Determining Repeatability Accuracy of 0.5HR

- High-speed step control, fast test speed

- ASTM E18, ASTM E384, ISO6508 GB/T 230

- New design, mobile nose, strong frame structure

- High-precision loading system, effectively avoiding force measurement overload

- High Precision Linear Guideway Controls Precise Head Moving

- Continuous measurement in and out of fixed worktable through automatic withdrawal function of indenter

- High definition LCD touch screen operation, menu operation interface

- Backlight LCD display, automatic data statistics and storage, RS-232 data output interface

- Automatic loading and unloading, adjustable holding time

- GO/NG Tolerance Judgment

- Correction of test values of cylinder and sphere

- Force Selection and Hardness Scale Selection Linkage

- Optional operating languages include English and Chinese for user’s convenience

- Scale conversion HR, HB, HV

- Built-in printer

- The standard is fully equipped to meet the test requirements of all scales.

Technical Parameters of JMHRS-150-XYZ Rockwell Hardness Tester

| Model | JMHRS-150-XYZ |

| System | Fully automatic end quenching, without adjusting the level of equipment, automatically compensate for sample deformation, the impact of ambient vibration on measurement |

| Executive standard | GB/T225,ISO 642,JIS G0561,SAE J406,ASTM-A-255 |

| Automatic focusing function | Full automatic;High、Middle、Low standard hardness block;Automatic Memory Calibration Data |

| Load system | High Precision Step Control System |

| Accuracy assurance | In the process of measurement, the workpiece deforms 50 mm, and the equipment can automatically compensate the deformation. |

| Allowable specimen height | 300mm |

| Distance from the center of indenter to body | 165mm |

| Start | Starting with one key, the probe automatically moves down directly from any position until it contacts the workpiece and completes the whole testing process automatically. |

| Interface | Chinese-English |

| Test scale | HRA、HRB、HRC、HRD、HRF、HRG、HRH、HRE、HRK、HRL、HRM、 HRP、HRR、HRS、HRV, HR15N、HR30N、HR45N、HR15T、HR30T、HR45T、 HR15W、HR30W、HR45W、HR15X、HR30X、HR45X、HR15Y、 HR30Y、 HR45Y |

| Conversion scale | HV、HK、HR、HB est., |

| Date output | RS232 |

| X-Y automatic test-bed | size:250×160mm;route:100×100mm;shape:365×300×140mm; The step control accuracy 0.001mm(1µm),Repeatability accuracy 0.01mmThe platform can implement multi-point setting, one key operation to complete multi-point automatic testing function. And can add other functions according to customer needs! |

| Z axis | Automation head moving, automatic ascending, positioning, one key to complete |

| Communication interface | RS232 |

| Power supply | AC90-240V 50-60Hz |

| Shape size | 540*280*735mm |

| Machine net weight | About 75kg |

HR-SD-A Rockwell Hardness Measurement Software, User Manual

Main functions of HR-SD-A Rockwell Hardness Measurement Software:

- Acquires single test data point from the Rockwell hardness test machine after each test

- Fetches all test data points stored in the test machine if applicable

- Plots the hardness curve

- Converts to other test scales

- Stores test data in the format of a single file for later retrieval

- Automatically save the test data and the statistics results for query

- Generates test reports in WORD or EXCEL formats

- Command the test machine in setting dwell time, selecting test scale, and starting test if applicable

- In the advanced version with motorized XY stage and Z up/down control, sets test patterns with specified XY coordinates, starts full automatic test with a single button click.