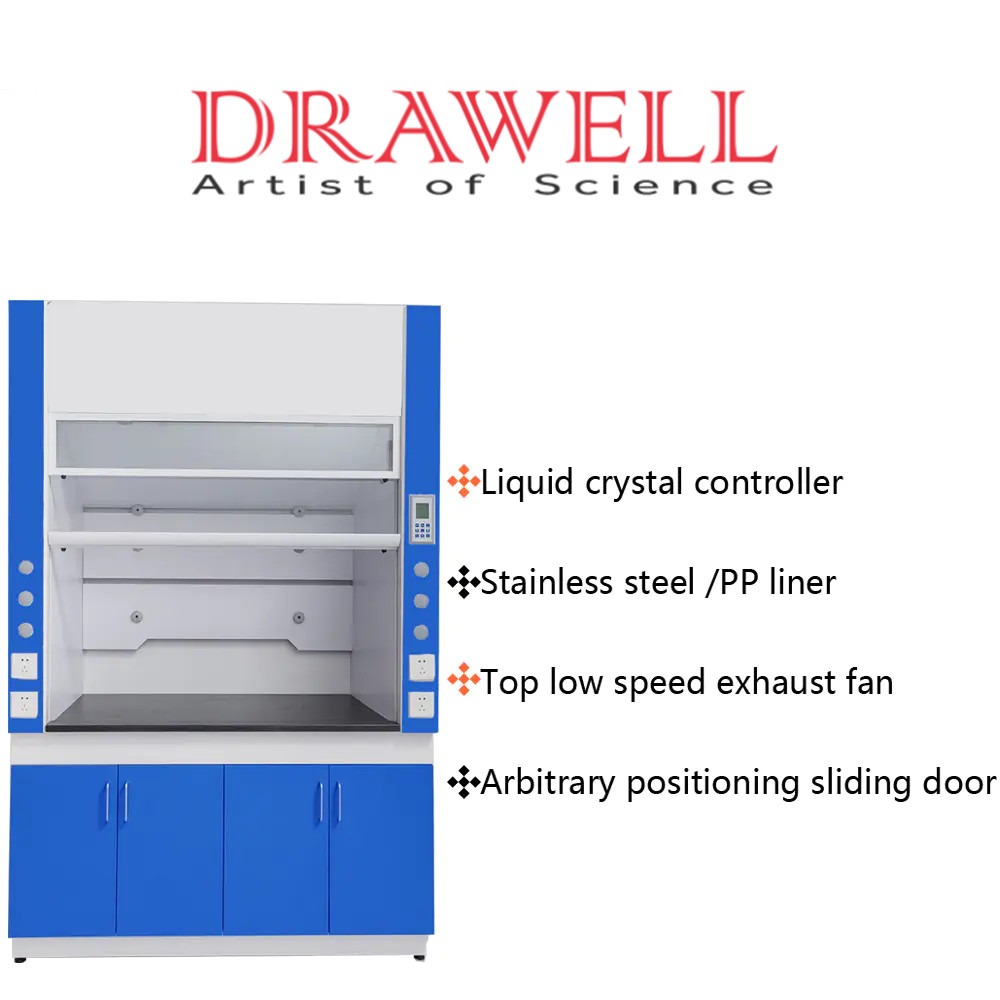

All Steel Fume Hood ZJ-TFG-12/15/18

TFG series ventilation cabinet is integrated with water, electricity, gas and ventilation. It is equipped with multifunctional socket inside. The window is designed into automatic balance type and is equipped with proper poise for taking its place easily.

Features of All Steel Fume Hood ZJ-TFG-12/15/18

- The outer shell material: The outer casing is made of high-quality cold-rolled steel plate of 1.0mm thickness in the machining center, which is cut, positioned, punched, bent and welded. After pickling and phosphating, the epoxy powder is sprayed and cured at elevated temperatures. High adhesion and aesthetics.

- The inner shell material: 5mm gray anti-double board, laboratory-specific materials. It has a detachable maintenance hole for easy maintenance of circuits, water and air lines.

- Operation surface material: It adopts 12.7mm solid core physicochemical plate countertop, acid and alkali resistant, chemical solvent corrosion, non-toxic and long service life.

- Fluorescent lamp: The fluorescent lamp is hidden at the top and does not come into contact with the airflow in the fume hood for easy replacement. It uses a 12W LED lamp with 5mm tempered glass.

- Handle material: pvc handle.

- Deflector material: 5mm anti-double board, laboratory-specific materials.

- Socket: Multi-function splash-proof power socket.

- Front window material: pvc plastic profile frame, the window is made of tempered glass, using stepless balance device, can move up and down, freely adjustable.

- Gas hood material: made of PP material, integrated, acid and alkali resistant, corrosion resistant

- Distribution box: Meets 220V and 380V power requirements, and is equipped with motor protection device.

- Control switch: 12V liquid crystal touch switch, centralized control of the entire circuit system.

- Equipment’s process Description: All steel plates were soldered with epoxy resin powder and visually observed without solder joints. All water, electricity and gas paths must be safe, suitable and concealed. Maintenance holes are provided on both sides of the cabinet for maintenance and safety inspection.

- Three baffles can discharge harmful gases of different height spaces from different areas. The fume hood exits the air in the fume hood at a working surface wind speed of 0.5 m/s to ensure that no residual gas is present. The ventilation efficiency is high, the exhaust air volume is about 1600m3 / h, and the noise is small.

- Lower cabinet material: 1.0mm high quality cold rolled steel plate (double layer), non-welded connection, removable pad. After molding, cutting, positioning, punching, bending and welding in machining center, after pickling and phosphating, the epoxy resin powder is sprayed and cured at a high temperature.

Technical Parameters of All Steel Fume Hood ZJ-TFG-12/15/18

| Model | ZJ-TFG-12 | ZJ-TFG-15 | ZJ-TFG-18 | |

| Working area size(W*D*H) mm | 985*595*1185 | 1285*595*1185 | 1585*595*1185 | |

| Overall dimension(W*D*H) mm | 1200*850*2350 | 1500*850*2350 | 1800*850*2350 | |

| Viewable Window | Using: x 5mm anti-explosion toughened glass, available to stop at any height of the rain slider, the main window can slide around | |||

| Top | solid physiochemical board/ Epoxy Resin board/ thickness 13/16/19mm/ catcher 26mm (optional) | |||

| Socket | anti-dust, splash proof safety socket with automatic closing lid, size of 60 x 60mm, 10A/16A /220V | |||

| Light | round energy saving light hidden in top ceiling, not directly contact with the air in the fume hood, easy to be replaced | |||

| Conlrd Panel | multl-functlon socket, lighting, fan and fan valve control | |||

| Sink | using imported PP material, chemical resistant, corrosion resistant and organic resistant | |||

| Tap | using copper material with high gloss epoxy powder spayed surface, acid and alkali resistant corrosion resistant providing single/double/triple outlet lypes for choice, with detachable nozzle and ergonomic PP handle | |||

| Sewer System | using high-densiiy imported PP trap, corrosion resistant chemical resistant and organic resistant, with filtering and smelly odor blocking function | |||

| Available Opening Height | 0~00 mm | |||

| FaceVelocity | 0.4—0.6m/s | |||

| Noise | <60db | |||

| Airflow Speed | 1080—1700m7h | |||

| Electricity | AC220V—380V/0.09—4kW | |||